Machine is supplied with staircase made from SS 304 pipe and SS 304 embossed sheet for anti silp property. SS 304 pipe hand railing is also provided. All components coming in contact with the product mix are made from SS 316 quality are highly polished. (We can supply machine with contact parts in any other quality of stainless steel on specific request). There are two impellers inside the bowl. Main impeller runs in horizontal plane and chopper or granulation impeller runs in vertical plane. Top lid is openable by mechanical system with hand using balancing weight or with the help of hydraulic + pneumatic system which is fully automatic process.

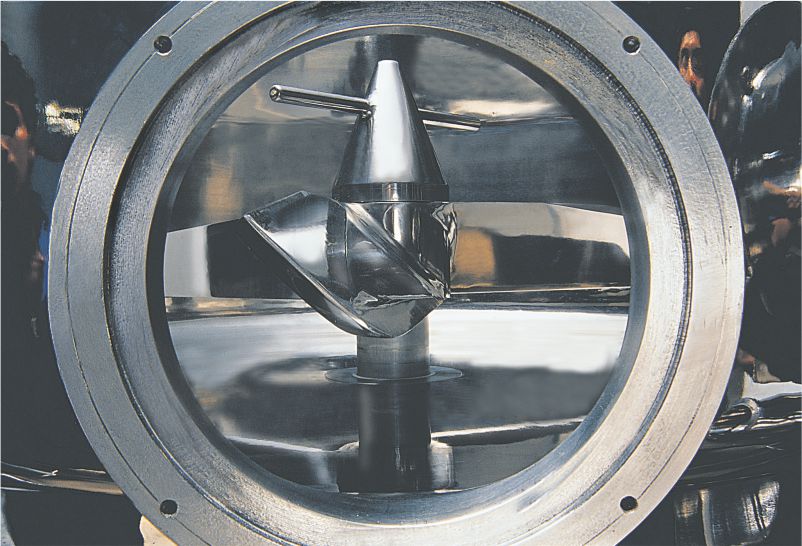

Main impeller is having unique design and blade angle, thus pushing the material radially outward. Face width of blade is also more. Entire impeller is thoroughly machined. Main impeller is supported on main shaft, which has its special two-stage housing. Two-stage housing totally eliminates any chance of cross contamination of product mix with bearing lubricants. Upper stage housing contains Labyrinth seal along with air purging facility. Lower stage housing contains ball bearing along with oil seals to make it completely leak proof. Thus, ball bearing housing is isolated from the vessel interior, totally eliminating mixing of grease into product content. Impeller with a unique dial plate mounting design facilitates for very easy removal with the help of JIG.

Chopper or granulation Blades is directly mounted on chopper shaft. Chopper housing is entirely made of SS316L having air purging and special seals. Chopper shaft is coupled to chopper motor by means of flexible coupling. It is fully automatic process controlled by PLC.

Machine has a pneumatically controlled discharge which is controlled by PLC.

Discharge piston is having a special profile to match the vessel interior, giving a perfect sealing arrangement, discharge assembly works on end flange on which discharge cylinder is fitted. This is a special type of non-rotating cylinder having a S.S piston mounted at one end, Discharge piston along with end flange can be swung open and complete cleaning of discharge pipe, piston and its seal is possible.

We can also provide main impeller lifting arrangement by which main impeller can be lifted by hydraulic + pneumatic cylinder by 100mm during washing process. With the help of main impeller lifting arrangement cleaning and visual inspection for validation process can be done easily.

Mixing bowl top lid has two openings, one for addition of paste and other for viewing granulation process. A vent is provided to release pressure in the vessel during mixing and granulation by a filter of 5 micron, it is easily washable, light assembly also provided for better viewing inside vessel.

To achieve consistency in the product quality it is desirable to minimize / eliminate the human elements in monitoring the operational parameters of the machine including the desirable to record / store the critical data which may contribute to product quality. Machine has provision to generate audit trial & batch report, alarm history and same will be printable. Machine should not start automatically if power resume and it should be restarted only by manual input if power resume. Set recipe. Parameters should not change & data should not loss due to power failure & communication failure. The operational recipe data can be saved. To incorporate suitable provision in the system of data storage.